The Magnetic Secret Inside Steel: How Hidden Atomic Forces Are Transforming Stronger, Cleaner Steelmaking

• Magnetic fields can quietly reshape steel at the atomic level

• Carbon atoms move differently when iron becomes magnetically ordered

• This discovery could cut energy use and emissions in steel production

advertisement

Introduction

Steel has shaped civilizations, skylines, and industries, yet one of its most powerful secrets has remained hidden in plain sight. For decades, scientists observed that magnetic fields could improve steel during heat treatment, but no one fully understood why. Recent research has finally uncovered the atomic mechanism behind this phenomenon, revealing how magnetism alters the behavior of iron and carbon atoms inside steel. This breakthrough not only solves a long-standing scientific mystery but also opens the door to stronger steel made with less energy and lower carbon emissions.

How Magnetism Influences Steel from the Inside

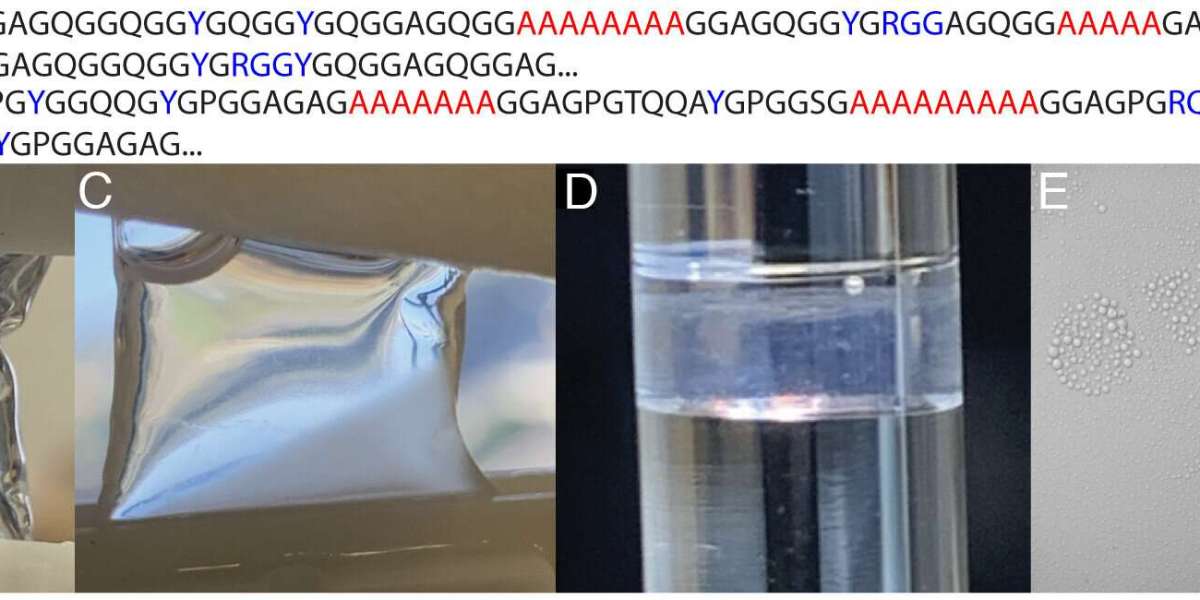

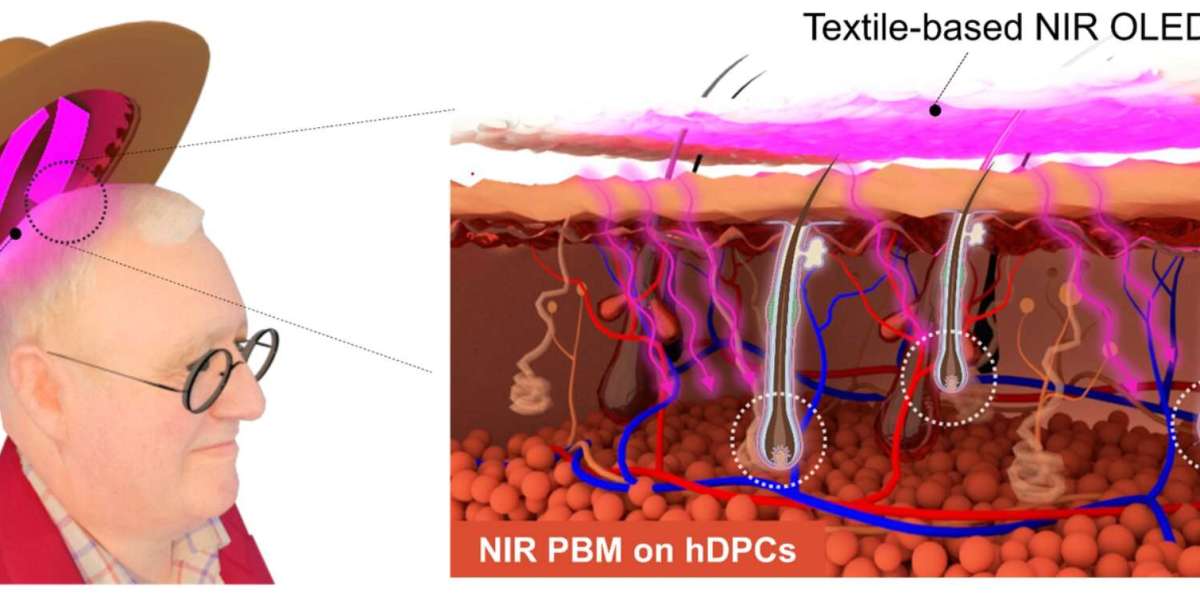

Steel is primarily an alloy of iron and carbon, and its strength depends heavily on how carbon atoms move through the iron lattice. These carbon atoms sit inside tiny octahedral spaces, often described as atomic “cages,” formed by surrounding iron atoms. According to new simulations published in Physical Review Letters and reported by ScienceDaily and Phys.org, magnetic fields change how iron atoms align their magnetic spins. When these spins align, iron becomes ferromagnetic, and this magnetic order raises the energy barrier that carbon atoms must overcome to move from one cage to another. As a result, carbon diffusion slows down, subtly reshaping the internal grain structure of steel and influencing its mechanical properties.

Why Heat Treatment Uses So Much Energy

Shaping steel’s microstructure typically requires extremely high temperatures, which explains why steelmaking is one of the most energy-intensive industrial processes in the world. Since the 1970s, metallurgists noticed that heat-treating steel under magnetic fields sometimes produced better results, but explanations were largely theoretical. As Professor Dallas Trinkle of the University of Illinois explains, earlier models were descriptive rather than predictive, offering no reliable way for engineers to control or optimize the effect. The new research changes that by providing a quantitative, physics-based explanation of how magnetic fields influence atomic motion in iron-carbon alloys.

advertisement

Simulating Atomic Motion Under Magnetic Fields

Using a sophisticated computational method called spin-space averaging, researchers simulated how temperature and magnetic fields affect iron atom spin alignment. These simulations revealed that near iron’s Curie temperature, where magnetic order changes rapidly, even modest magnetic fields can strongly influence atomic behavior. When magnetic spins are more random, carbon atoms find it easier to move. When spins align, the atomic cages become more restrictive, slowing carbon migration. Both ScienceDaily and Phys.org report that this clear link between magnetism and diffusion finally explains observations that puzzled scientists for over 50 years.

Implications for Cleaner, Smarter Steelmaking

The implications extend far beyond academic curiosity. By understanding how magnetic fields slow carbon diffusion, engineers may be able to design steel-processing methods that rely less on extreme heat. This could significantly reduce energy consumption, lower production costs, and cut CO2 emissions. The researchers also suggest that these principles may apply to other alloys, enabling scientists to predict and control diffusion in a wide range of materials using magnetic fields rather than brute-force heating.

Conclusion: A New Era for Steel Engineering

The discovery of steel’s magnetic secret marks a turning point in materials science. What was once an unexplained observation is now a powerful, predictive tool that links magnetism, atomic motion, and material performance. By harnessing magnetic fields to guide carbon atoms more efficiently, the steel industry could move toward a future that is not only stronger and smarter, but also cleaner and more sustainable. Sometimes, the biggest industrial revolutions begin with the smallest forces—hidden deep inside the atoms themselves.

Key Points

Magnetic fields alter iron atom spin alignment, changing carbon diffusion

Slower carbon movement reshapes steel’s internal grain structure

The discovery could reduce energy use and emissions in steel production

advertisement

Frequently Asked Questions (FAQ)

What is the magnetic secret inside steel?

It is the discovery that magnetic fields change how iron atoms align, which increases the energy barrier for carbon atoms to move through steel.

Why does carbon movement matter in steel?

Carbon diffusion controls steel’s microstructure, which directly affects strength, durability, and performance.

How can magnetic fields reduce energy use in steelmaking?

By slowing carbon diffusion without relying solely on high temperatures, magnetic fields may allow lower-energy heat treatments.

Does this apply only to steel?

Researchers believe the same principles could apply to other alloys, enabling broader control of material properties using magnetism.

Who led this research?

The work was led by Professor Dallas Trinkle and colleagues at the University of Illinois, published in Physical Review Letters.

Sources

- ScienceDaily – Research summary on how magnetic fields slow carbon diffusion in steel

https://www.sciencedaily.com/releases/2026/01/260125083427.htm - Phys.org – Detailed report on magnetic fields altering energy barriers in iron

https://phys.org/news/2026-01-magnetic-fields-carbon-migration-iron.html

Thank you !