article image source: phys.org (Link)

Turning Plastic Waste into Valuable Chemicals with Single-Atom Catalysts

Innovative Approach to Recycle and Upcycle Polystyrene Waste

Plastic pollution has become one of the most pressing environmental challenges of our time. Every year, millions of tons of plastic waste end up in landfills and oceans, posing risks to human health and the environment. However, researchers are developing groundbreaking solutions to tackle this problem, one of which is transforming plastic waste into valuable chemicals that can be used in industrial applications.

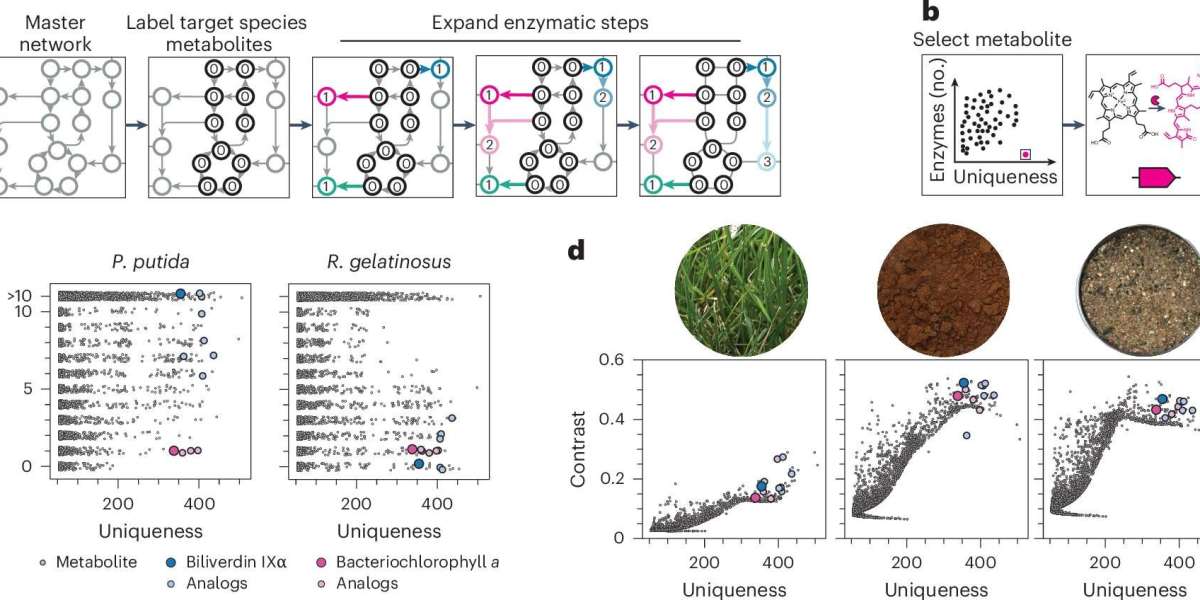

A recent breakthrough in this area comes from researchers at Nanjing Forestry University and Tsinghua University. They’ve found a way to convert a commonly used plastic, polystyrene (PS), into toluene, a valuable hydrocarbon widely used in manufacturing and chemical industries. Their innovative process, outlined in a study published in Nature Nanotechnology, uses cutting-edge technology—single-atom catalysts.

advertisement

The New Approach to Recycling Plastic

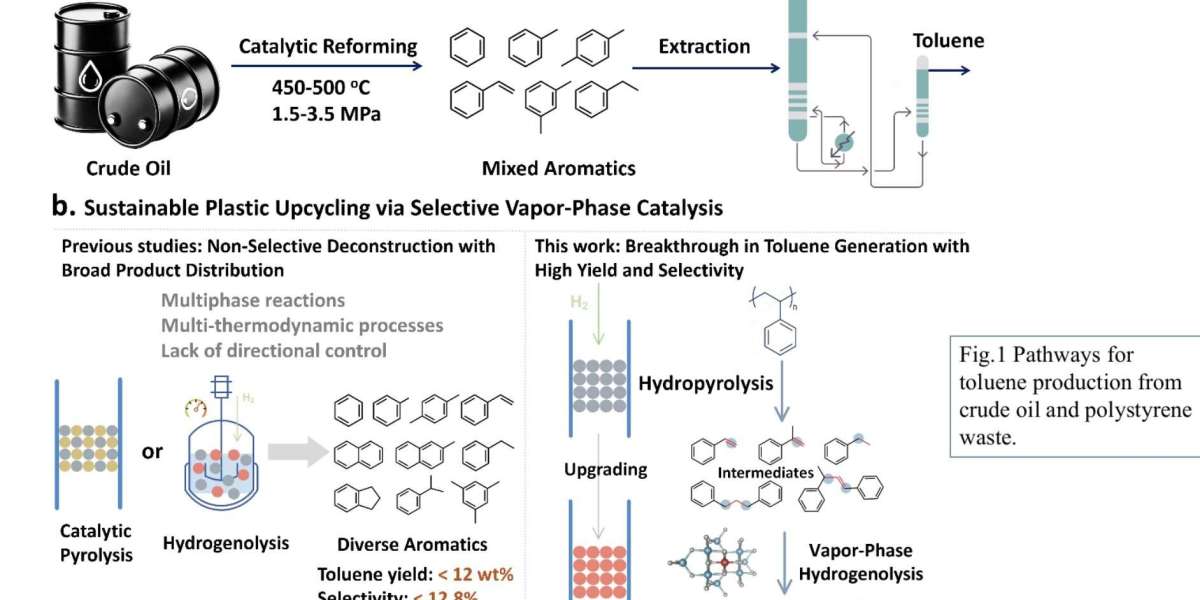

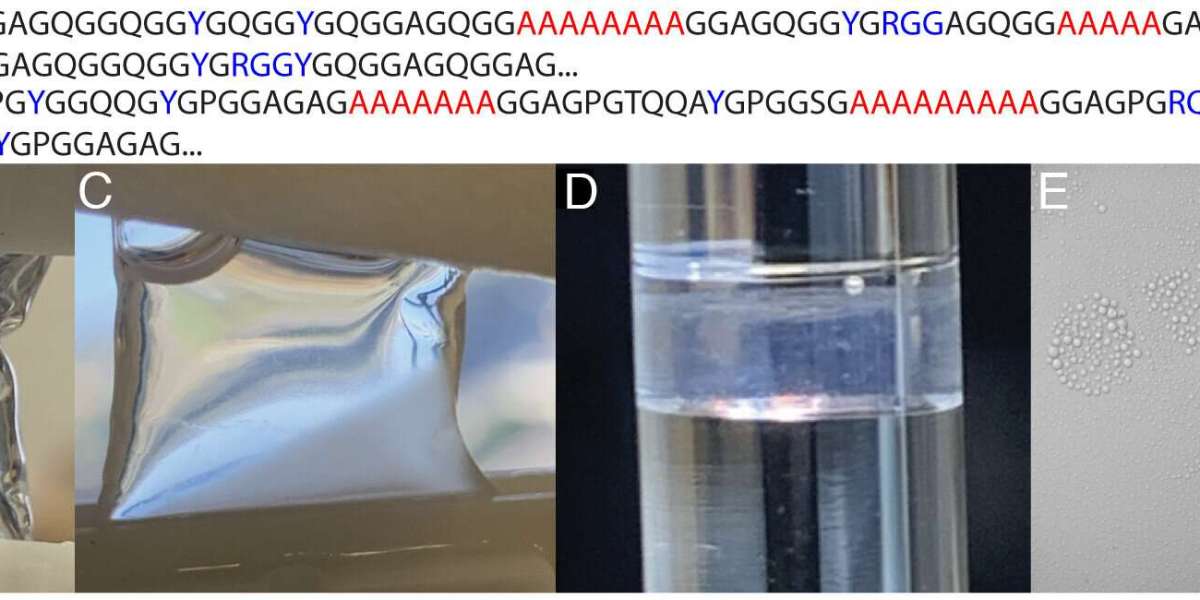

The process begins by breaking down polystyrene waste into smaller molecules. Polystyrene is a plastic commonly used in food packaging, disposable cups, and other consumer goods. Traditionally, recycling this plastic has been challenging. However, this new method involves two steps: pyrolysis and hydrogenolysis.

Pyrolysis: In the first stage, polystyrene waste is heated to high temperatures. This heat causes the solid plastic to break down into smaller vapor molecules.

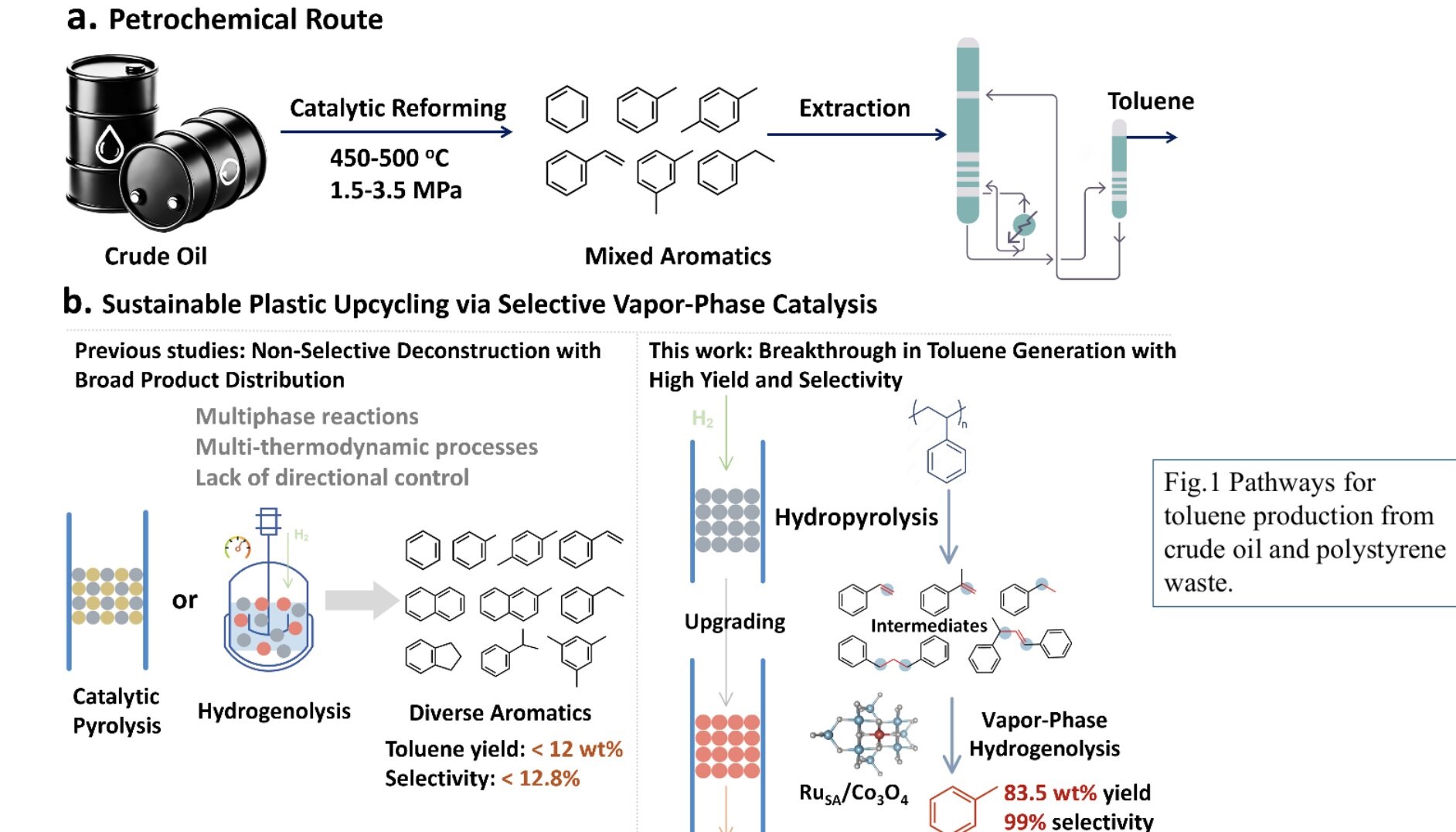

Hydrogenolysis: These vapors then flow into a second part of the reactor where hydrogen gas and a special catalyst are introduced. This reaction breaks the chemical bonds within the molecules, shaping them into the desired product—in this case, toluene.

Dr. Zedong Zhang, one of the lead researchers, explains, "We found that tuning the active centers of ruthenium (Ru) at the atomic level allows us to control the product selectivity, enabling us to convert polystyrene waste into toluene with high efficiency." The catalyst helps make this process more efficient by speeding up the reactions without being consumed.

Why This Method is a Game Changer

This new approach has the potential to drastically reduce the environmental impact of plastic waste. In their lab tests, the team achieved an impressive conversion rate: over 99% selectivity for toluene with a yield of 83.5%. Even more significantly, the method reduces the carbon emissions associated with toluene production by 53% compared to traditional methods.

Not only is this process more environmentally friendly, but it is also more cost-effective. The estimated cost of producing toluene through this method is $0.61 per kilogram, which is cheaper than the industry standard.

Looking to the Future

The team’s work doesn’t stop here. While the current research focuses on turning polystyrene into toluene, the technology could be adapted to create other valuable chemicals or even fuels. The researchers plan to further develop the system to improve selectivity and scale up the process, making it more viable for industrial use.

Dr. Zhang adds, "Our future research will focus on improving the selectivity of the catalysts to better control the distribution of products. We also plan to refine the reactor design to allow for continuous plastic feeding, which will enable longer operation times and larger-scale plastic conversion."

With continued advancements, this technology could play a key role in the global effort to reduce plastic pollution, transforming waste into a valuable resource.

advertisement

Conclusion: Turning Waste Into Opportunity

The research into single-atom catalysts for plastic upcycling opens up new possibilities for dealing with the growing plastic waste crisis. By turning waste into valuable chemicals, this innovative process not only offers an environmentally-friendly solution to plastic pollution but also demonstrates how cutting-edge science can address real-world problems. As we move forward, such breakthroughs will likely become crucial in building a more sustainable future, where waste is no longer a burden, but a resource to be valued.

Sources:

Thank you !