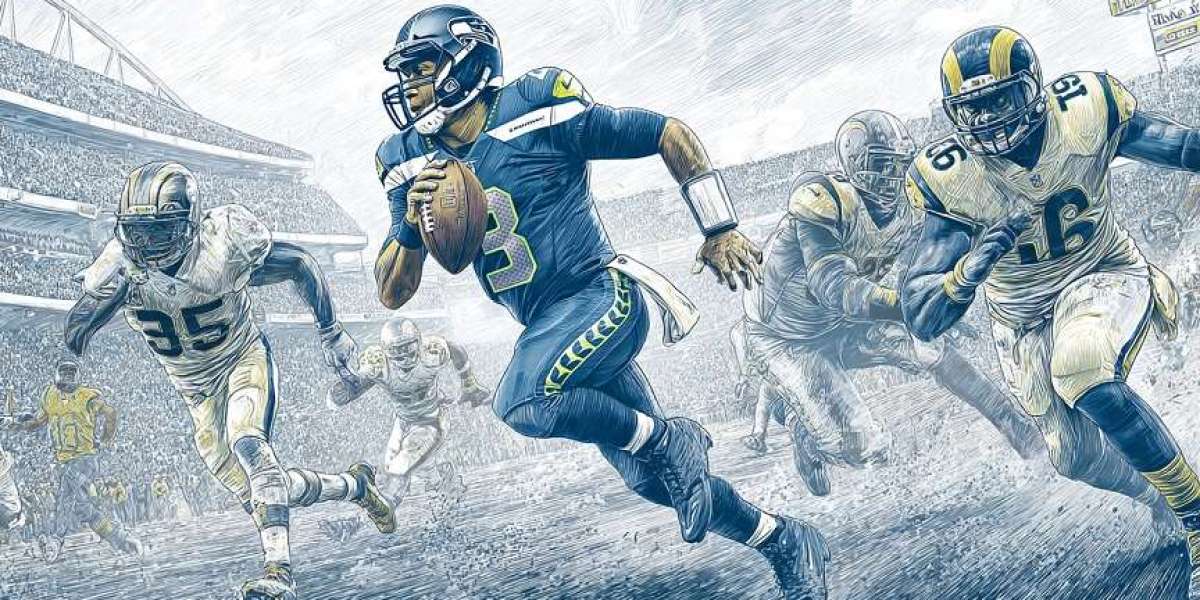

article image info & copyrights:

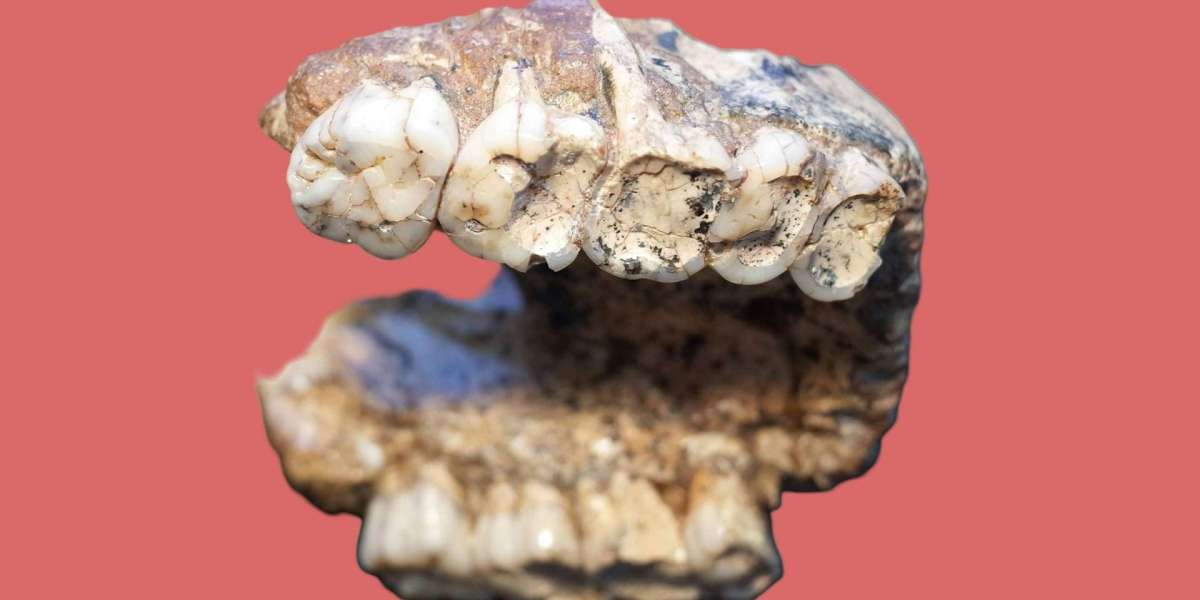

Enzymatic structural material (ESM), a strong, durable, and recyclable construction material. Credit: Worcester Polytechnic Institute

- source: phys.org (Link)

New Carbon-Negative Construction Material Promises Faster, Cleaner, and Smarter Building

New Carbon Negative Construction Material Promises Faster, Cleaner, and Smarter Building

A new bio-engineered construction material developed at Worcester Polytechnic Institute can absorb CO₂, cure within hours, and match the strength of conventional concrete—opening a new path for sustainable, fast, and resilient building.

advertisement

A Growing Need for a Cleaner Building Future

Concrete shapes nearly every human-made environment—houses, schools, roads, bridges. But its environmental cost is enormous. Traditional cement production alone generates about 8% of global CO₂ emissions, placing it among the world’s most polluting industries. For every ton of cement produced, almost a ton of carbon dioxide is released.

To address this challenge, researchers are turning to new approaches that could alter how we build our world. One of the most promising breakthroughs comes from a team at Worcester Polytechnic Institute (WPI), led by Professor Nima Rahbar.

A Material Inspired by Nature, Built by Enzymes

Rahbar’s team developed a new type of construction material called Enzymatic Structural Material (ESM)—sometimes referred to as a form of biological concrete. Rather than relying on extremely high heat and fossil-fuel–intensive processes, ESM is formed through a gentle, bioinspired chemical reaction.

The key lies in an enzyme named carbonic anhydrase. Found naturally in many living organisms, including human red blood cells, this enzyme rapidly binds carbon dioxide and reacts it with calcium. The reaction forms solid calcium carbonate—essentially limestone—directly between grains of sand.

Instead of mining limestone and firing it at 1,450°C, ESM grows its mineral structure at room temperature.

Researchers mix the enzyme with sand and hydrochar, a carbon-rich scaffold made from organic waste. This mixture creates a stable internal structure similar to how water reinforces a sandcastle—except this one hardens into stone.

Fast Setting, Strong Results

One of the most striking advantages of ESM is its speed.

While conventional concrete can take up to 28 days to reach full strength, ESM cures in hours, reaching its maximum strength in less than a day. This speed opens possibilities for rapid construction, especially in emergency or disaster-response scenarios.

In early testing, the material achieved a compressive strength of 25.8 MPa, meeting the typical standards for residential and commercial concrete. According to reports, it also maintains stability when exposed repeatedly to moisture—something many biobased materials struggle with.

A Net Carbon-Negative Material

The climate implications are significant. For each cubic meter produced:

Traditional concrete emits ~330 kg of CO₂

ESM absorbs more than 6 kg of CO₂

Both major sources agree on this comparison, though they express it slightly differently. One source cites 6 kilograms of CO₂ sequestration, while another specifies 6.1 kilograms—a negligible difference attributed to experimental variation.

Regardless of the exact decimal, the outcome is clear:

ESM doesn’t just reduce emissions; it reverses them.

This shift—from emitting 330 kg to absorbing CO₂—has been described by researchers as one of the most dramatic reductions in the building industry’s history.

Recyclable, Repairable, and Moldable

Beyond its sustainability and speed, ESM offers practical advantages.

It can be:

cast into molds

sprayed onto surfaces

repaired easily

recycled for reuse

These traits could reduce long-term maintenance costs and substantially decrease construction waste sent to landfills. Its potential applications include wall panels, roof decks, modular components, and portable structures.

The Road to Real-World Adoption

Despite its promise, researchers note that cost estimates remain uncertain, since the studies are still small-scale. However, enzyme production is becoming cheaper, and removing the need for high-temperature kilns could eventually make ESM economically competitive with concrete.

Industry uptake may be slow, as construction companies often prefer familiar materials. But according to the researchers, once carbon pricing, long-term maintenance savings, and rapid curing are considered, the advantages become hard to ignore.

Some sources emphasize the industry’s conservatism as a challenge, while others stress the growing urgency for alternatives—two perspectives pointing toward the same need for innovation.

Still, the message from the research community is consistent: even partial adoption of carbon-negative materials could have an enormous global impact.

Conclusion: A Possible Turning Point for Sustainable Construction

Humanity has relied on concrete for centuries, shaping every city and landscape in its path. But with climate pressures escalating, the world needs cleaner, faster, smarter solutions. ESM shows that nature’s strategies—quiet, efficient, and elegant—may hold the key.

If materials like ESM move from the lab into mainstream construction, we could witness one of the most significant shifts in building technology since the invention of modern cement. Lower emissions, faster construction, improved durability, and a path toward truly circular architecture: these are not distant dreams, but achievable possibilities.

The “Age of Concrete” may not be ending, but it could be evolving—into something lighter, greener, and more in harmony with the planet we depend on.

Sources

Phys.org – New construction material absorbs CO₂ and sets quickly for sustainable building

https://phys.org/news/2025-12-material-absorbs-quickly-sustainable.htmlZME Science – Scientists Just Created a Biological Concrete that Heals Itself and Is Carbon Negative

https://www.zmescience.com/research/materials/cement-alternative-carbon-negative/

Thank you !