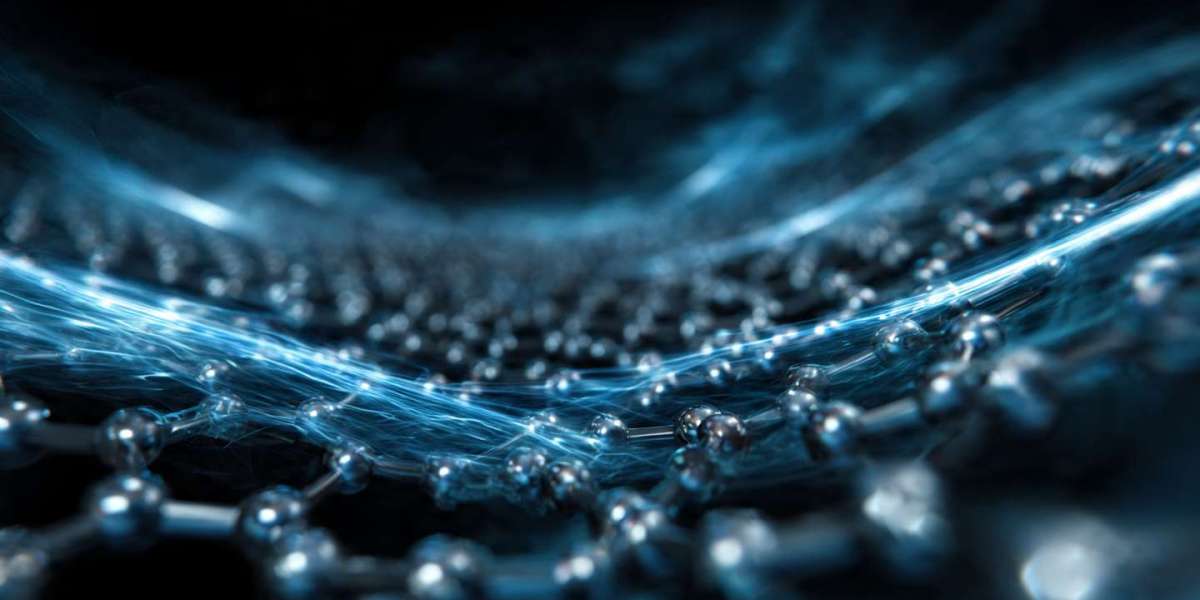

article image source: statnano.com (link)

What if the next generation of electric motors didn’t rely on copper or aluminum at all? That’s the bold direction taken by researchers at the Korea Institute of Science and Technology (KIST), who have built a working electric motor using cables made entirely of carbon nanotubes (CNTs). The ambition: to create lighter, more efficient—and more sustainable—motors for vehicles, aircraft and beyond.

advertisement

The innovation at a glance

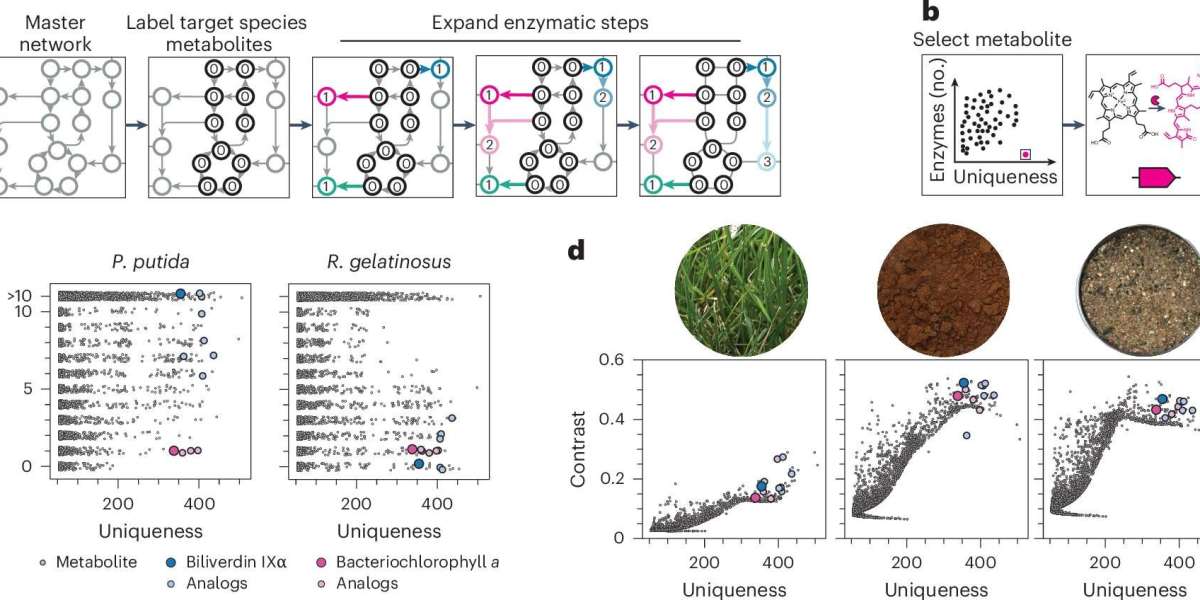

Traditional motors use copper wiring because copper offers excellent conductivity. But copper has drawbacks: it’s heavy, it has supply-chain and cost issues, and it can generate waste heat and require substantial cooling. The KIST team decided to replace copper entirely with a new class of wiring: core-sheath composite electric cables (CSCECs) made from aligned carbon nanotubes encased in a thin insulating jacket.

Here are the standout details:

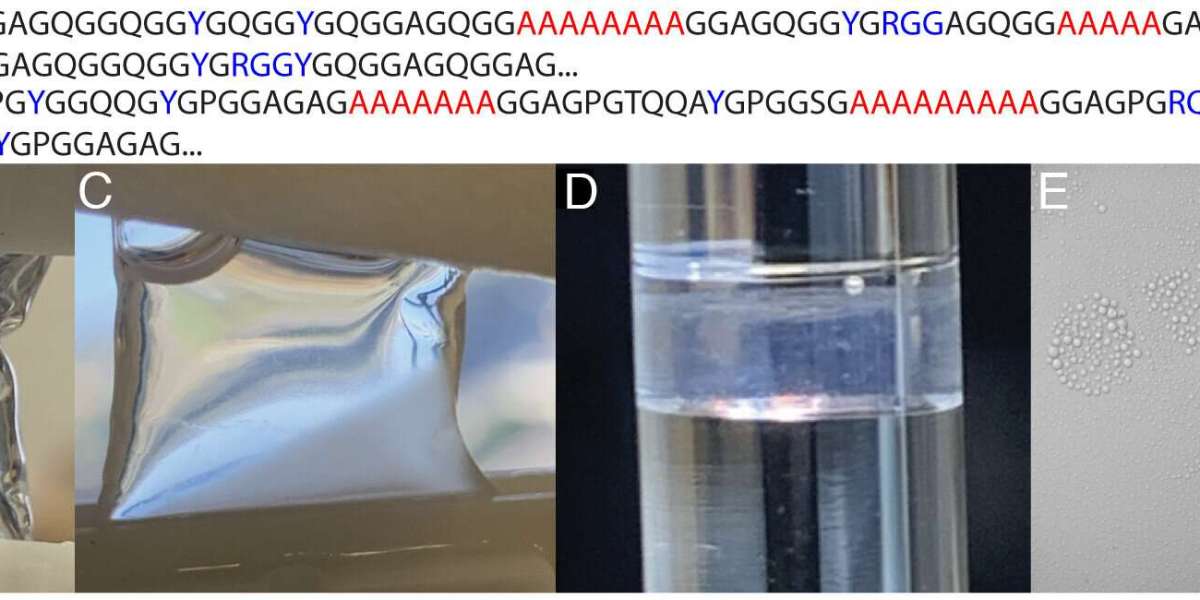

The cable core is made of continuous nanotube wires, aligned using a fluid-phase alignment process called Lyotropic Liquid Crystal Assisted Surface Texturing (LAST). This helps ensure the conductors behave more like a unified wire rather than a bundle of misaligned parts.

The prototype cable achieved a conductivity of ~7.7 million S/m (siemens per meter). By contrast, copper sits at ~59 million S/m.

The density of the CNT wire is roughly one-fifth that of copper, which means major weight savings—an important metric for applications where every gram counts.

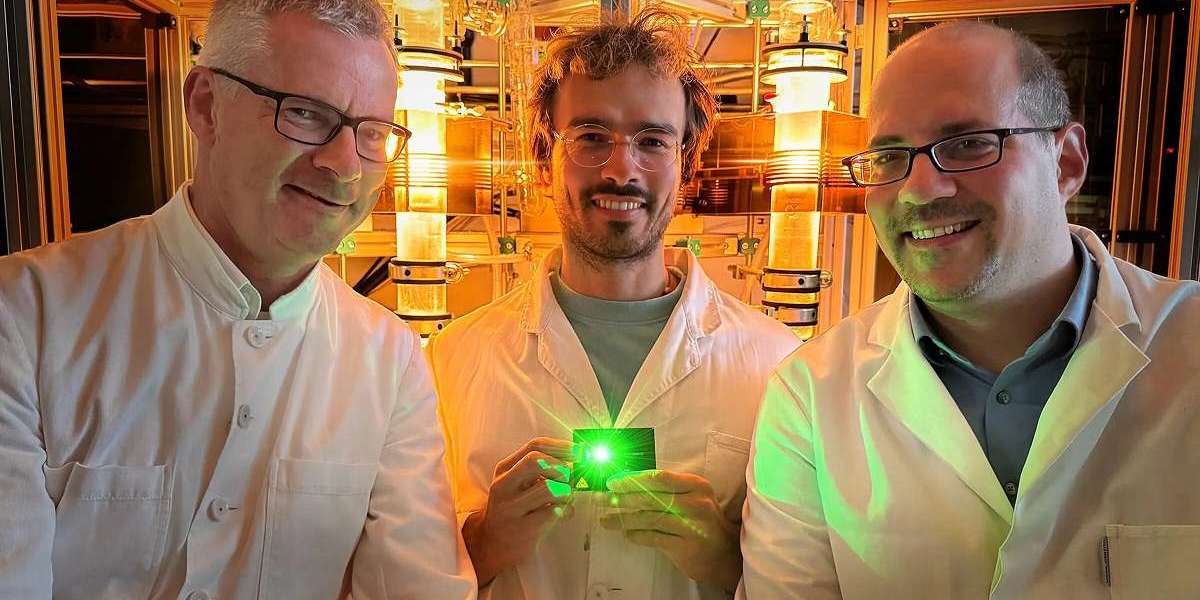

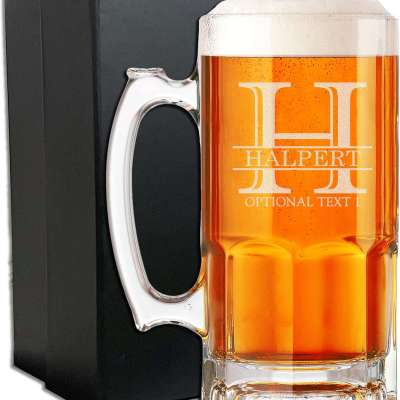

In a demonstration, the motor using CNT wiring ran at ~3 volts, achieved ~3,420 rpm, and powered a small toy vehicle. While the traditional copper version reached ~18,120 rpm under the same voltage, the CNT version shone in terms of weight-to-performance ratio.

Thickness and flexibility: the cable is only ~0.3 mm thick including insulation (~256 µm core with ~10 µm sheath) in some versions.

The toy car, the motor, the CSCEC wire, and the CNT - image source: newatlas.com

Why this matters

The implications are significant. In electric vehicles (EVs), planes, drones and industrial machinery, wiring and motors contribute to overall system weight. Lighter motors mean less energy required to move the vehicle, better battery efficiency, longer range and reduced material use. For example:

In a dual-motor EV, replacing copper windings with CNTs might drop the motor weight significantly (some hypothetical estimates suggest a drop from ~68 kg to ~52 kg for a comparable dual-motor setup) by virtue of lower density and less material required.

Beyond just weight, reducing dependency on heavy metals like copper means access to alternative supply chains, and potential reductions in manufacturing and recycling emissions.

Some CNT sheets have shown recyclability, offering a circular-economy angle for high-performance wiring materials.

Technical and scaling challenges

Despite the promise, several hurdles remain before this becomes mainstream:

Conductivity: While 7.7 MS/m is impressive for CNT wiring, it still falls well short of copper’s ~59 MS/m. That means for the same size and voltage the CNT version may carry less current or require redesigns to compensate.

Junction resistance: When bundling many nanotubes into a practical wire, the places where those individual tubes meet (junctions) increase resistance and reduce overall performance compared to an ideal single nanotube.

Manufacturing & cost: Producing long, uniform, low-impurity CNT fibers is complex and costly today—some estimates suggest $375–500 per kg vs around $10–11 per kg for copper.

Certification, safety & durability: Motors in cars/aircraft must undergo crash, thermal, vibration, insulation, connector and repair-standard tests. New materials mean new standards.

Environmental and health safety: While lightweight, nanotubes pose nanomaterial risks (such as exposure in manufacturing or end-of-life). Responsible recycling and solvent recovery are essential.

What’s next?

The KIST team is already working on refining several aspects:

Increasing coil thickness and optimizing harness geometries so the material can carry higher voltages and larger currents akin to automotive applications.

Improving heat dissipation and insulation layer design to handle higher power and more aggressive duty cycles.

Scaling up production processes for long-length cables, ensuring uniform quality, and lowering cost.

Exploring broader use of the technology beyond motors: wiring harnesses, flexible conductors, robots, aerospace.

A broader look: Why this fits the future

In the shift toward electrification, efficiency isn’t just about battery chemistry—it’s also about every supporting component. Reducing weight, lowering material dependence, and increasing recyclability are all part of the equation. The work by KIST isn’t just about a new motor coil—it’s a signpost of what’s possible when materials science meets mobility demands.

Reducing the weight of a motor part may seem incremental, but multiply that across thousands of vehicles, drones, aircraft and machines, and the effect on energy use, emissions and resource strain becomes meaningful. Moreover, as metals like copper face supply pressure and increasing environmental scrutiny, alternatives become increasingly attractive.

Conclusion: A Motor of Many Possibilities

The new carbon nanotube motor from KIST isn’t just a laboratory novelty—it could be a stepping stone to a lighter, leaner, more sustainable future of motion. Imagine an electric car where wiring harnesses weigh a fraction of what they do today—or an aircraft or drone with motors so light they unlock new flight times and payloads. Picture manufacturing lines where heavy-metal wires are progressively replaced with ultra-light carbon structures that can be recycled in closed loops.

That future isn’t here yet—but the vision is clear. The motor that doesn’t use copper is more than a technical curiosity; it’s a challenge to the status quo of how we think about power, materials and movement. As the CNT-based wiring matures, the question shifts from “Will this work?” to “How quickly can we make this real?”

In a world racing to decarbonize and electrify, every gram saved, every resource conserved, every innovation scaled counts. With the KIST team’s breakthrough, a new wire made of carbon is quietly turning into a new wire for the world’s motors. And that’s a powerful change.

Sources

“Goodbye to copper: Korean scientists invent an electric motor with carbon nanotubes”, Earth.com

“Copper takes a back seat: a new kind of motor rewires the future”, Manufacturing Today India.

“Radical electric motor runs without metal coils”, New Atlas.

“South Korean researchers developing copper-free electric motor”, Electrive.

Thank you !